Analytics support

Impregnation system check

Total support for the Impregnants you are using and the impregnation process.

Inspection of impregnating equipment in use

We will inspect the Impregnation System and process. By using specialized equipment to check various points such as the condition of the vacuum pump, the actual pressure conditions, and the level of dirt in the cleaning tank, we can discover problems more quickly and support stable production.

We will also submit the inspection report to the person in charge on the same day.

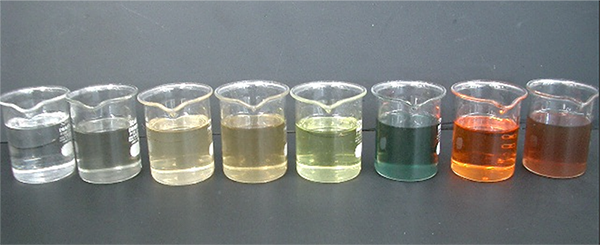

Inspection of Impregnants in use

We perform performance tests using appropriate test items depending on the type of Impregnants, and submit the test report to the person in charge at a later date.

1.Density

The density of the Impregnants is measured according to JIS K 0061(Japanese Industrial Standards), and the presence of impurities and deterioration are investigated.

2.Viscosity

The viscosity of the is measured according to JIS K 7117, and the presence of impurities and deterioration are investigated.

3.Stability

By measuring specific substances contained in the Impregnants, the stability of the Impregnants itself is evaluated on a 10-point scale. The value decreases due to refrigerator malfunction or foreign matter such as metal powder being mixed in. Lower numbers increase the risk of unexpected hardening of the impregnant.

4.Reactivity

The curing time of the Impregnants is measured and the reactivity of the Impregnants itself is evaluated on a 10-point scale. The value decreases due to contamination with impurities and multiple other factors. If the value is low, the Impregnants may not harden within the specified process time and the sealing performance may deteriorate.

5.Moisture content

Measure the moisture content in the Impregnants according to JIS K 2275. It increases due to condensation in cooling pipes and moisture brought in from previous processes. In particular, if pre-drying is insufficient, moisture may be present in the micropores, which may prevent the Impregnants from penetrating properly.

6.Others

A specialized inspector visually checks for discoloration and foreign matter contamination. Enter information if there is a risk of affecting the quality of the Impregnants or after impregnating.

Analysis support equipment

We will support you with any problems that may occur during the impregnation process.

1. Submerged pressure test device

A test piece is used to confirm whether the impregnation process has achieved the desired airtightness. It is also used for various durability tests.

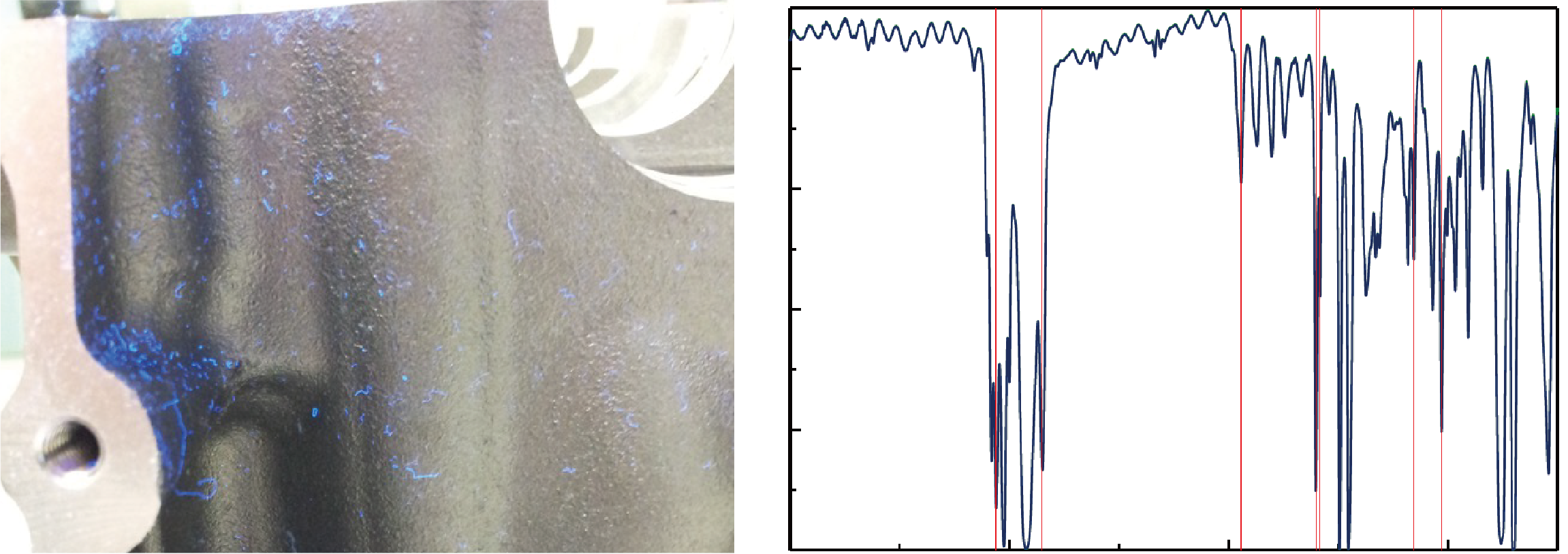

2. Fourier Transform Infrared Spectroscopy

Used to identify substances attached to parts. This allows us to determine whether the product originates from our products or from other processes, and take appropriate countermeasures.

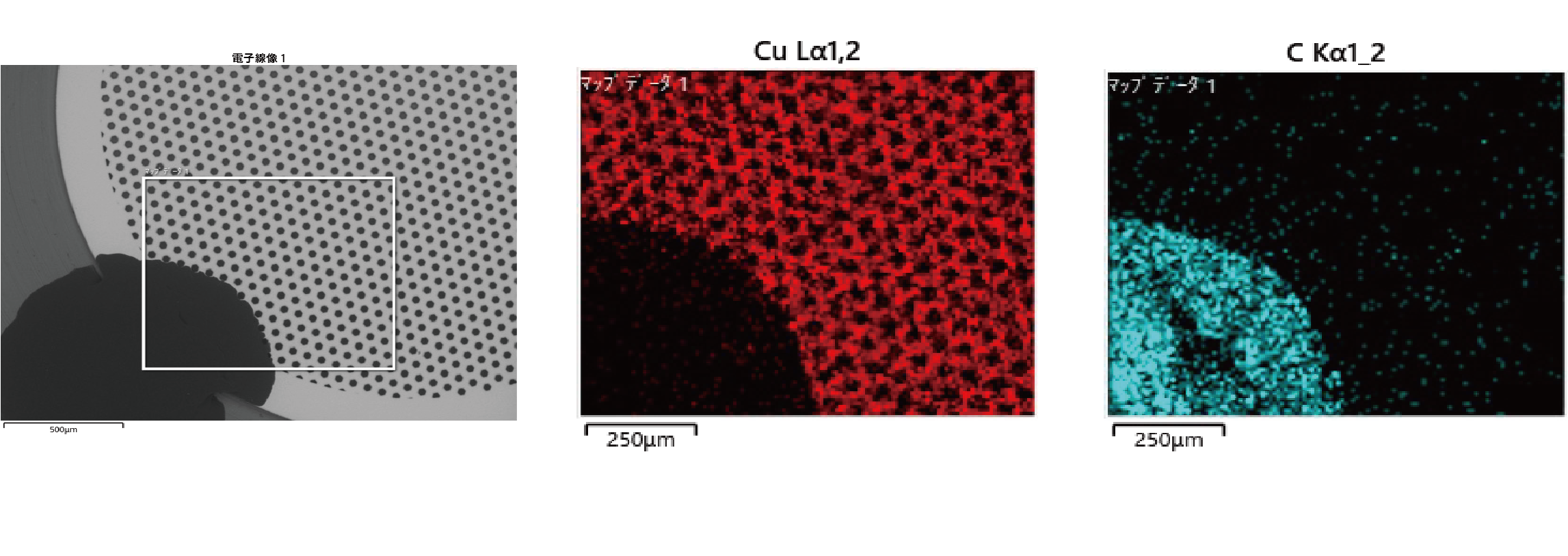

3. Scanning Electron Microscope & Energy Dispersive X-ray spectrometry

Performs elemental analysis including deposits on the surface of parts. This helps solve problems such as discoloration and deposits.

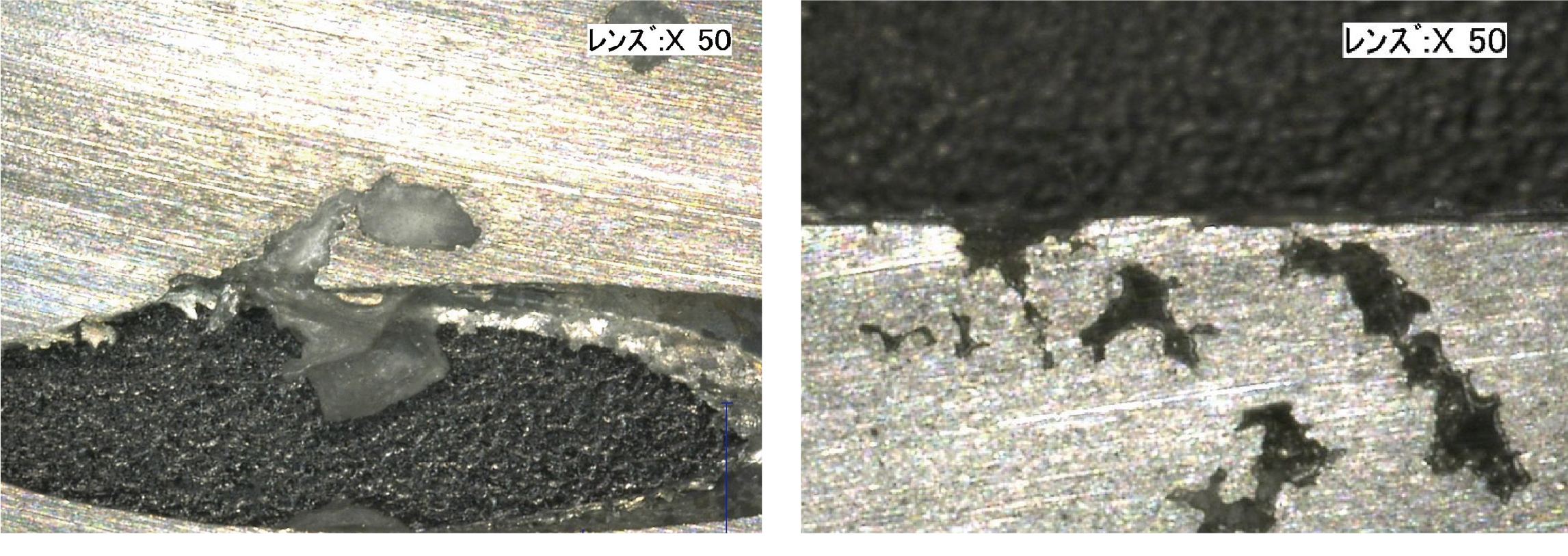

4. Optical microscope

Enlarge and check the micropores. Used when checking a wider area than SEM-EDX.

5. Gas chromatography/high performance liquid chromatography

We perform impurity inspections such as Impregnants and Washing agents.

6. Thermal analyzer(TG-DTA/DSC/TEM)

Analyze the thermal properties of the Impregnants.

7. Others

We provide total support for impregnation using many other analytical devices and specialized equipment.